Wood Boilers- indoor/outdoor, open/closed,

gasification……what???

Will someone just level with me?

I have been in the Fire/Hearth/HVAC/Building industries for

over 32 yrs. The one thing I know for

sure is that I don’t know everything……….the following is just my honest

assessment based on my experience.

One of the reasons I love what we do is because I’m always

learning new things. Our goal as a company is very simple; help folks cut

through the “hype” and figure out what they need to accomplish their goal. Our

job in my opinion is to tell the truth and give honest advice based on our experience,

what works and what may not meet the customer’s expectations. Obadiah's Woodstoves and Wildfire Fighters

Please visit our website for one of the largest selections of Boilers found anywhere. We have a large selection of residential, commercial, agricultural and industrial indoor and outdoor boilers. Commercial Waste Oil Boilers, Commercial Biomass Furnaces , Commercial Biomass Boilers, Commercial Pellet Boilers , Commercial Coal Furnaces , Commercial Coal Boilers , Commercial Wood Furnaces, Commercial Wood Boilers . We offer waste oil, trash burning boilers that burn cleanly from Glenwood Boilers. Waste Oil Boilers We also offer Coal, Pellet, Chip and Corn burning boilers from Traeger, Americas Heat, Pelco, WoodMaster, Glenwood, Portage and Main, as well as Biomass Boilers that will burn anything from sawdust to horse manure from Glenwood and others. Coal, Corn, Chip, Pellet and Biomass Boilers We specialize in North American built high efficiency gasification boilers from Econoburn, Woodmaster Flex Fuel, Pro Fab Elite and Portage and Main Economizer. North American Gasification Boilers We offer European import Gasification Boilers from Attack, Biomass, Effecta, and EKO. European Gasification Boilers We also offer simple non electric boilers like the AquaGem by DS Stoves. Non Electric Amish Wood Boilers and Furnaces Obadiah's has special liquidation sales occasional and occasionally you can find super deals like what we're offering on the Greenwood boilers now, from Pro Fab Industries. Greenwood Liquidation Boilers And Furnaces

Please visit our website for one of the largest selections of Boilers found anywhere. We have a large selection of residential, commercial, agricultural and industrial indoor and outdoor boilers. Commercial Waste Oil Boilers, Commercial Biomass Furnaces , Commercial Biomass Boilers, Commercial Pellet Boilers , Commercial Coal Furnaces , Commercial Coal Boilers , Commercial Wood Furnaces, Commercial Wood Boilers . We offer waste oil, trash burning boilers that burn cleanly from Glenwood Boilers. Waste Oil Boilers We also offer Coal, Pellet, Chip and Corn burning boilers from Traeger, Americas Heat, Pelco, WoodMaster, Glenwood, Portage and Main, as well as Biomass Boilers that will burn anything from sawdust to horse manure from Glenwood and others. Coal, Corn, Chip, Pellet and Biomass Boilers We specialize in North American built high efficiency gasification boilers from Econoburn, Woodmaster Flex Fuel, Pro Fab Elite and Portage and Main Economizer. North American Gasification Boilers We offer European import Gasification Boilers from Attack, Biomass, Effecta, and EKO. European Gasification Boilers We also offer simple non electric boilers like the AquaGem by DS Stoves. Non Electric Amish Wood Boilers and Furnaces Obadiah's has special liquidation sales occasional and occasionally you can find super deals like what we're offering on the Greenwood boilers now, from Pro Fab Industries. Greenwood Liquidation Boilers And Furnaces

I have spoken with several folks who called me because they now have

an outdoor boiler sitting in their back yards with CONDEMEDED DO NOT USE sticker

on it. Worse yet, the unit is only a couple of years old.

I have spoken with several folks who called me because they now have

an outdoor boiler sitting in their back yards with CONDEMEDED DO NOT USE sticker

on it. Worse yet, the unit is only a couple of years old.

What happened you ask? They qualified for financing and the

largest outdoor boiler company in the world was there with an aggressive sales

force and before they knew it that had a note for anywhere between $10-20k

depending on their installation. Did anybody ever take the time to tell them

that there was a potential EPA problem looming on the horizon……….or that their

community was fixing to outlaw outdoor boilers…….no, the sale was more

important than the truth.

.jpg)

Outdoor boilers, why the bad rap? Well very simply…….most

don’t burn very clean and are simple smug pots that smolder all day long. Top

that off with a customer who has never burned wood before, or worse, a trash

burner who thinks he now has an incinerator…….and you have a recipe for unhappy

neighbors. Combine someone with asthma,

or other respiratory problems and things can get really bad fast.

.jpg) There are some very simple designs that will never work if

you’re trying to achieve a clean burn.

In order to burn fire needs three things, fuel, air, and heat = COMBUSTION.

To burn clean, wood needs to burn very hot, the hotter the better = the cleaner

burn you get.

There are some very simple designs that will never work if

you’re trying to achieve a clean burn.

In order to burn fire needs three things, fuel, air, and heat = COMBUSTION.

To burn clean, wood needs to burn very hot, the hotter the better = the cleaner

burn you get.

Outdoor Boilers………..think about that for a few

moments…………let it sink in. Outdoor boilers are almost an oxymoron when you

really think about it. You are taking the very expensive boiler and pumps that you’re

using to heat your home, or shop……..and sticking it outside in the coldest possible

place. Does that really make that much sense? Yeah ok, get the wood and bugs

out of the house, I’m all for that, no problem, but I ask you what about the

wood you are going to put in your nice new shiny wood outdoor boiler? Are you

planning on dumping it on the ground out in the middle of the yard and dig your

wood out of the rain snow and mud and use that to feed your boiler. If so, you’ll

be sadly disappointed. Wet, green wood does not burn well. Furthermore it

stinks and more than half the BTUs are consumed drying out the wood so it can

burn. Even with the “most efficient boiler”, your efficiency will still would

drop by half and the chimney will plug up with creosote and become a fire hazard.

Underground Insulated Pipe- The Good, The Bad, The Ugly

Truth…..

95% of all underground pipes leave no gaps between the feed

and return PEX lines. When you consider

the BTU bleed off factor you get when you bury this low R value pipe in the

ground, not to mention the very low R-Values, I wonder how the contractor could

sleep at night. So many BTUs are cancelled out in the pipe before they reach

the place where the BTUs are needed. In a

water to air heat exchanger, this can be a problem on really long runs. My

advice is, if you’re going with an outdoor boiler, run two corrugated lines

with two hot feeds in one pipe and two cold returns in the other. Don’t skimp here;

otherwise you’ll be heating the ground next to your home and not your home or

shop. Here is a good place to see what has happened to others. http://www.hearth.com/talk/threads/insulated-underground-pex.48808/

I have heard that some of the underground PEX pipe companies

claim less than 1 degree heat loss in 100’……..please… Let’s take a simple look at this idea

and see how much sense it all makes to you.

When you look closely at underground PEX pipe you’ll find lots of

variations. In my opinion, you want the highest R value possible for as long as

possible. The ground is a cold damp place and most insulation will become

waterlogged and lose their R-values. In

most high efficiency wood boiler installs we are looking for as many BTUs per

pound of wood as possible. To do this requires that most of the BTUs stay

inside the PEX until they arrive where they are most needed. Therefore we use

two separate lines, one for the feed, and one for the return. I run them

separately instead of all inside one pipe, because it is very hard to insulate

the cold return from the hot feed inside one pipe. Of course most outdoor wood

boilers are so inefficient, line loss does not matter either.

I like to lay my pipe in a

trench that has a layer of at least 2” thick rdgid foam that is about 14” wide

and is laid in the bottom before I lay the pipe. I then lay the Feed and Return

pipe’s on top of the foam. We then call in an insulation contractor who sprays

the entire trench with at least 24” of foam. We then cover it with heavy gauge

plastic to shed moisture and bury it. We lose very little BTUs to the soil.

I have seen folks build a

trough from foam panels and ply wood, lay in their ThermoPEX and fill with Foam

beads and closed off. They build a roof over it all and have easy access if

they have a problem later on down the road.

Heat

Handlers and Water to Air Heat Exchangers-The Truth

Few folks will tell you the

truth about forced air systems. Air is a great insulater - just look at your new high effeciency thermal

windows. How do they work? There is an

air space under vacuum and in some cases injected with Argon gas to further

increase thermal effeciency. Very simply,

air is a fantastic insulator.

Heat handlers are an easy way

to make heat; they also allow folks with forced air furnaces to utilize hot

water heat and realize some cost savings

compared to burning fossil fuels. If you

live in an area where you need air conditioning most of the year, then forced

air makes sense and I would not worry much about effeciency loss either.

If you already have forced

air and want a wood boiler to cut your fuel bills, it is not that difficult to

add a water and air heat exchanger into your exsisting plenum, to make hot air.

You do not need to run radiant flooring or baseboards to make it work.

The Pro Fab Heat Handler is a

complete self contained plug and play system that works great with the HPBA

Vesta Award Winning Elite 100 and 200

Gasification boilers.

Man has been burning wood as

a renewable, carbon neutral fuel for thosands of years. It is only recently that we have given much

thought to what is coming out of the chimney.

We Americans do seem to be

behind the curve in this realm. There are some wonderful new North American products

out there, but in reality, the Europeans have been at this game a long time.

They have it down pretty good if you are comparing a high tech gasification

boiler to a firebox submerged in water.

Some manufacturers added

catalytic combustors and a new replaceable product for their dealers that needs

servicing every year and replacement every few years. The better manufacturers

played around with secondary combustion.

By injecting air into the top of the firebox they found they could

reburn the gasses and get more heat and less smoke. Today the best woodstoves

do not rely on catalytic combustors.

The EPA is now taking a long

hard look at wood fired boilers. The only boilers that will meet the new

regulations, are the newer style gasification boilers that have been used in Europe

for over 30 yrs! http://www.health.ny.gov/environmental/outdoors/air/owb/purchase.htm

Did you realize that in

Switzerland it would be illegal to sell or install a typical North American

outdoor wood boiler which has been sold and installed by the tens of thousands

across North America? The same holds true for most of Europe. They are amazed

that we would burn such an outragous product and even more stunned at how popular

they are here. But that is changing rapdily as folks begin to do their homework

online and can see how the rest of the world does it.

To burn solid fuels such as

wood efficiently, you need complete combustion. For complete combustion you

need 3 things - fuel, air and ingnition. How you control that process determins

how well combustion occurs. By moving the combustion below the

firebox where the wood sits, you super heat the fuel which vaporizes as a gas,

the gas is drawn through a funnel which is re-combustion occurs at aprox 2000 degrees.

There is very little particulate that escapes the chimney. Instead of smoke

there is water vapor.

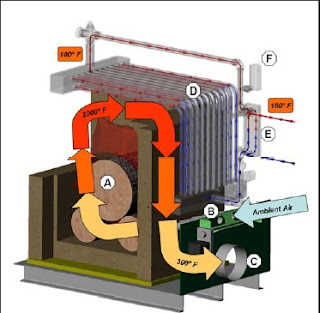

Here are some various

pictures of gasfiaction boilers where the combustion chamber is below and

combustion is controlled through variable speed blowers and oxygen controls. As

you can see by the way the fire burns and how hot it gets, the thick refractory

reflects all that intense infrared energy back raising the combustion temps

like that of a steel blast furnace, far higher than if it were surounded with

water and steel. The Pro Fab Elite is a good example shown on the right below.

The pictures demonstrate

how a wood gasification boiler works. Combustion takes place at extreme

tempertures below the firebox, essentially cooking the cordwood in the firebox

above. As the wood cooks it releases gasses which are then burned cleanly.

Other

high effeciency wood boiler designs

The Seton/Greenwood boiler is

a very simple yet efficient design. It works well as long as it is properly

installed. As with all solid fuel

boilers, it is imperative that the heat exchanger inside the boiler return

side, never fall below 140 degrees or it will condensate and corrosion will begin

to the boiler itself.

A few benefits to the

Seton/Greenwood is that it converts the

wood to coke when it is not calling for heat, so it can be used without water

storage. When the temp calls for heat the draft opens and reignition occurs

instantly if the unit has built up thermal energy inside the boiler from

several weeks use. This boiler can burn large full rounds without a problem. It

is much more forgiving to operate and burn, even if your wood is not perfectly

seasoned. It is also mechanical so it is very reliable and not prone to power

surge damage.

This is the million dollar

question, in my my humble opinion water storage is the best way to go, if you

can make it happen. Let me explain it the way the Europeans view effcient hot

water solid fuel boilers.

Picture this, you have a

gallon of fuel and you have a generator. You need to produce eletricity to

power your home. Running a large generator at an idle all day long does not

make a gallon of fuel go very far, but run the generator at a more efficient

speed and use that power to charge your battery bank. You can then draw a

little power as needed later and the generator does not need to run except to

charge the battery bank again. Depending on how frugal you are with your stored

energy, will determin how long you can go on a charge.

Letting any solid fuel boiler

idle for days is a very inefficient use of the wood, even a high efficiency

gasification boiler does not retain that efficiency at idle.

All boilers burn best at optimal

temperatures. It is a good idea to have water storage for any boiler

installation, because the same principle exsist in all solid fuel appliances - you can not shut the fire down once started as

you can with gas or oil by turning on and off a valve to control the flow of

fuel. Once the wood is lit it takes a while to achieve good combustion temps. It

is not good to stop, or interupt the process once it has begun. It is best to

burn hot and store the energy in as large of tanks as your installation BTU

demands dictate. It is best to do an energy audit and figure out the BTU load

in the worst of weather. Then you can figure how many BTUs you should be able

to store to last you between fires. We had a customer that was an over the road

trucker who was home every other week. He

loved it that he could go 9 days in the coldest of weather before having to

fire his boiler, so his wife did not have to bother with it at all.

Next comes choosing a good gasification

boiler. Today in North America you have far more choices than you did just 10

yrs ago. Pioneers like Craig Issod of www.hearth.com saw the handwriting on the wall and began importing the HS Tarm line of

boilers way back when. These were cutting edge technology back then and there

were few competitiors. Others soon followed and now you also have many options

to pick from in European gasification boilers. Polish imports like EKO and

BioMass offer a big bang for the buck. The new Effecta boiler is a Swedish

built contender utilizing Lambda Technolgy. The Vigas has gained populairty particularly

back east. If you want to stay North American made, the Pro Fab Empyre Elite

series offers a great value for the price. The Woodmaster Flex Fuel Boiler is a

state of the art US/German venture that is awesome and also utilizes Lambda

Technolgy.

Where

to install your wood boiler?

If you want the smoke and

mess out of the house, I agree. Add a shed

on the back of the house, or build a freestanding boiler house to shelter your

boiler and the wood you’ll be feeding it.

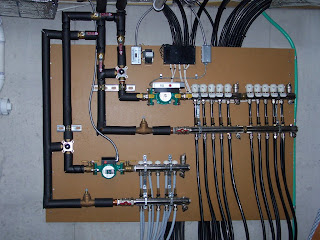

Here are some pictures of a perfect installation in my opionion. Hopefully they will give you some ideas on how best to plan your new wood boiler installation.

This is a very professional clean installation belonging to our customer Charlie Woltz. We can not take credit for this installation, but it is something everyone would be proud of.

It is very well thought out

and clean! It is obvious that the installer really took pride in their

workmanship. There are many componets to a properly installed boiler system. If

installed properly, a wood fired boiler system should give you 30 yrs of

trouble free service.

Open

or Closed System, what does that mean and what are the benefits?

The easiest way to explain

this is to compare a boiler system to a vehicle cooling system. On a vehicle,

the cooling system is closed. There is a

pressurized cap that will vent if the tempertures get to hot and the system

begins to boil over. Rather than exploding, the cap releases the presure and

the fluid escapes. There is also a thermosat in the system which opens and

closes according the coolent temps. When the vehicle is cold in the morning,

the thermosat is closed and recirculates the water through the engine block, allowing

the engine to reach operating temps faster. Once the engine is warm, the thermosat

opens and coolent flows through the system, regulating the tempertures to the engine

so it runs at optimum temps. Now picture your wood boiler as the engine and the

cooling system as your radiant heating system. They are very similar in design.

The main benefit of a closed

system is that the water will not boil as quickly and it boils at a hotter

temperture than 220 degrees which is where water boils at sea level. That changes with elevation. So in a nut shell,

you can run a boiler hotter under pressure than you can an open system.

So why would you want an open

system? The main reason is saftey, an open system is not presurized and

therefore can not explode if improperly installed. In many places it is a crime

to mess with a pressurized boiler system if your not properly licensed to do

so. Many people have died in boiler explosions over the years, so the

authorities are pretty strict for obvious saftey reasons. Properly installed,

pressurized boilers are as safe as any domestic hot water tank.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)